|

_

Day 11

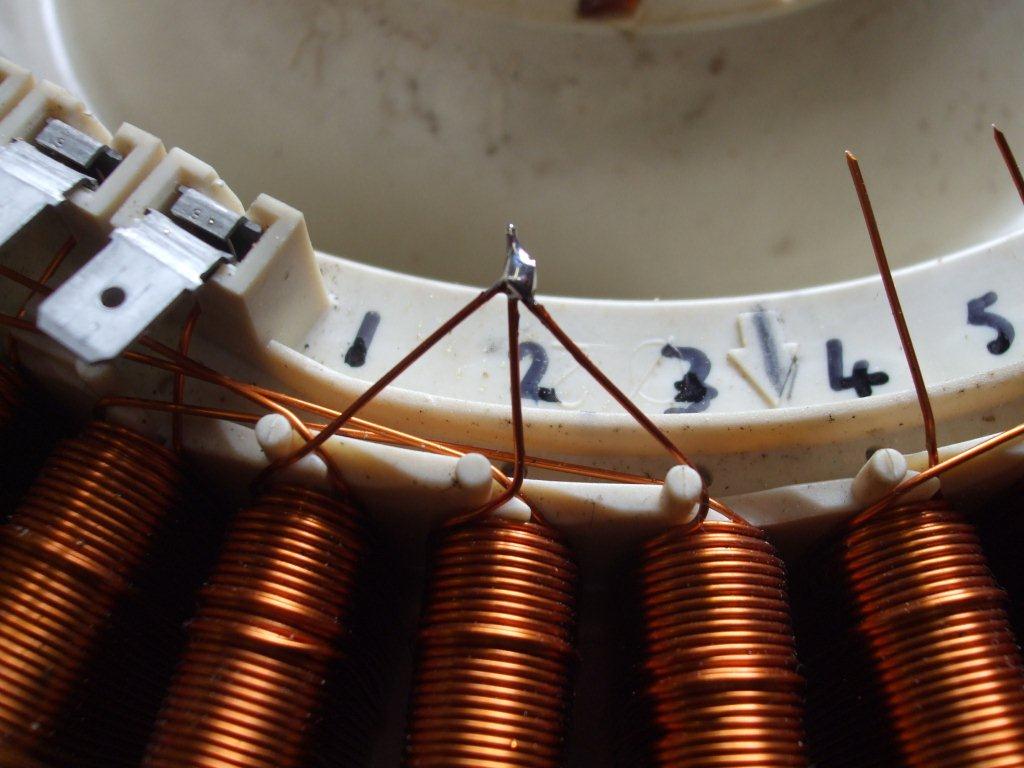

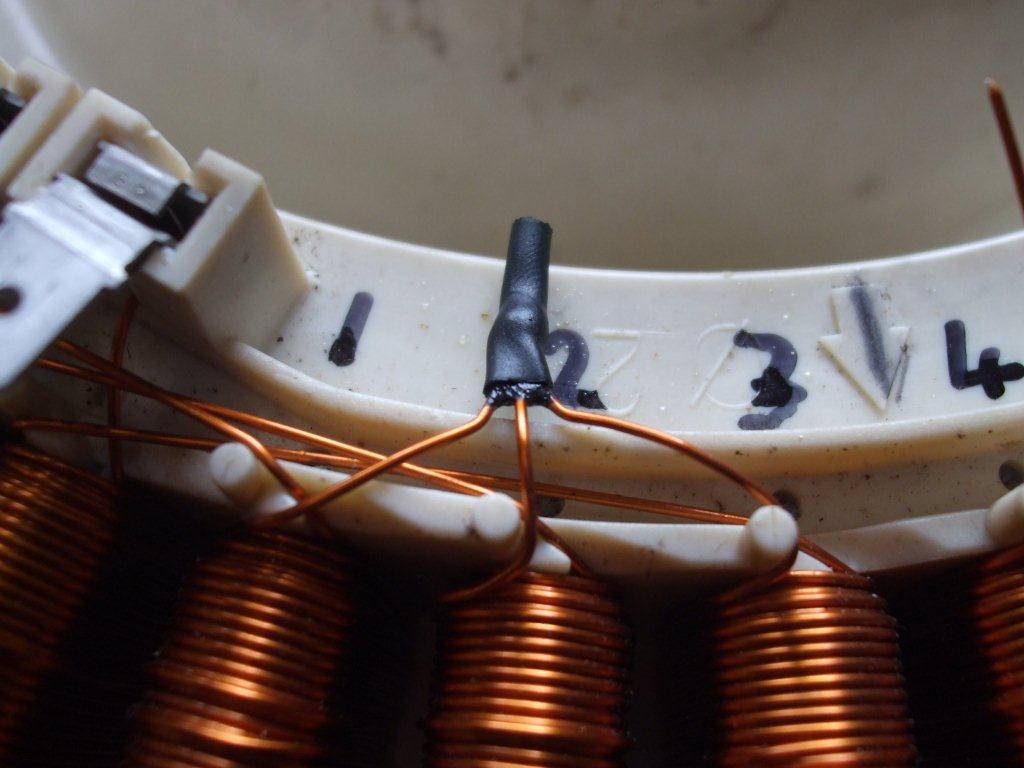

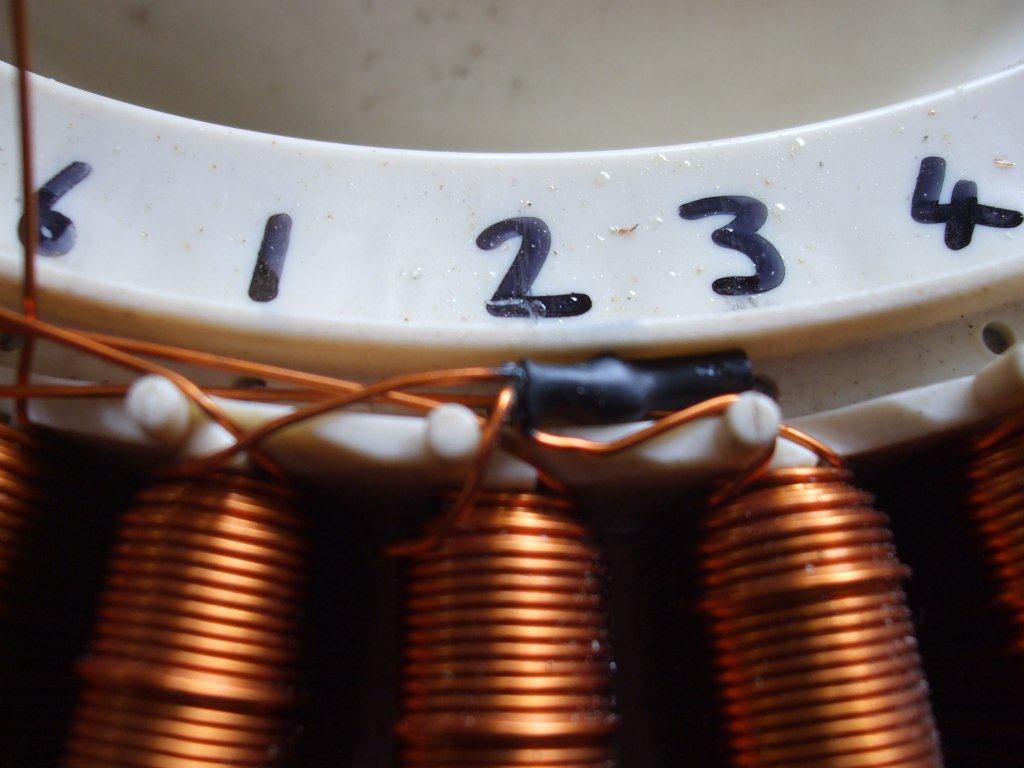

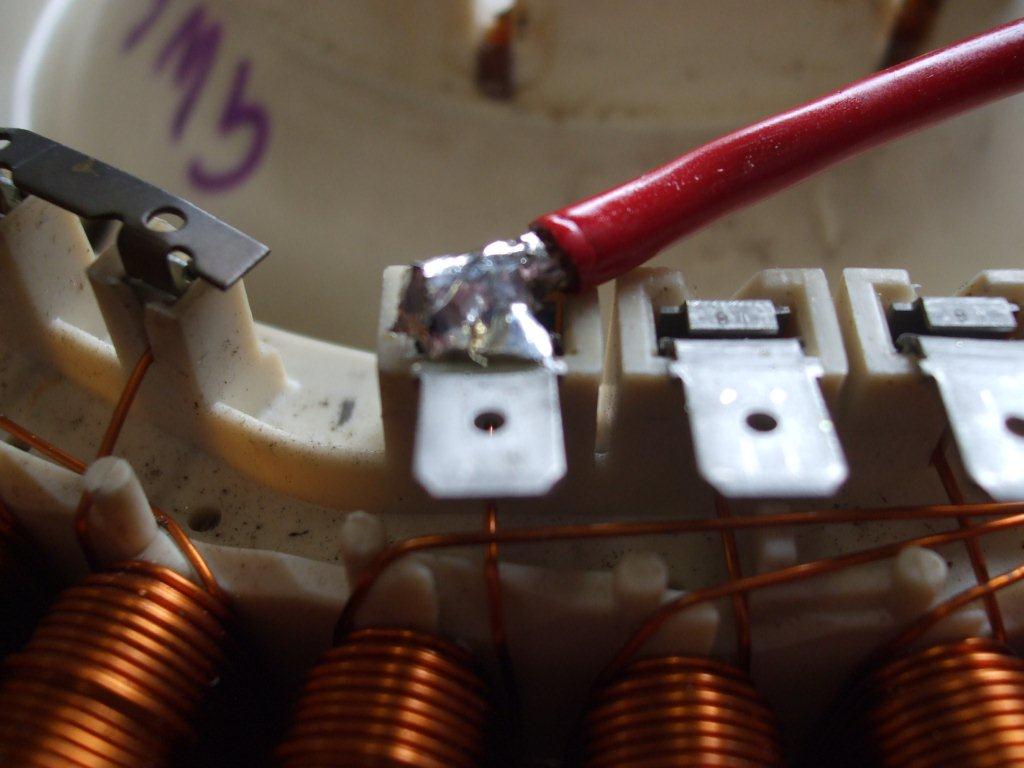

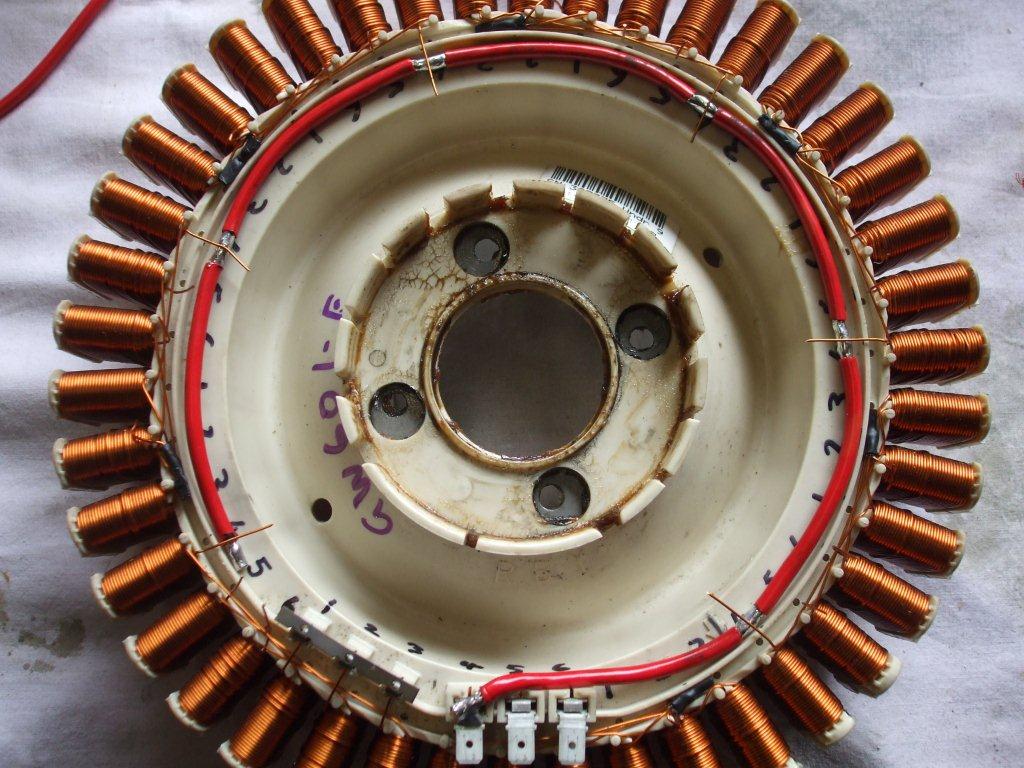

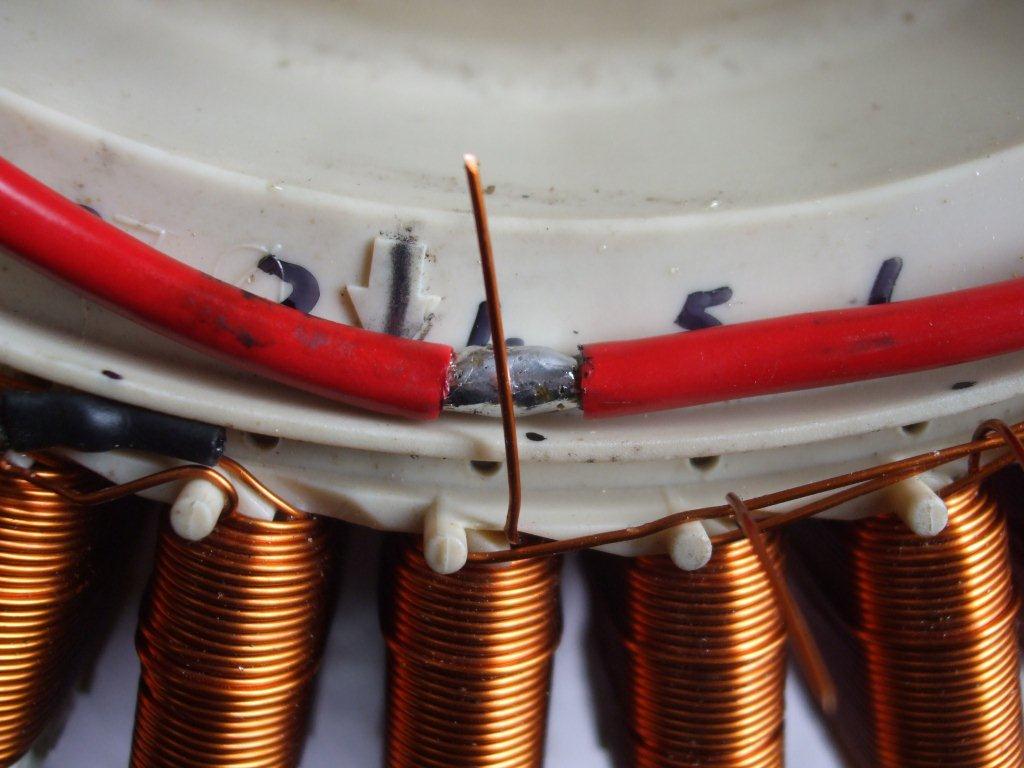

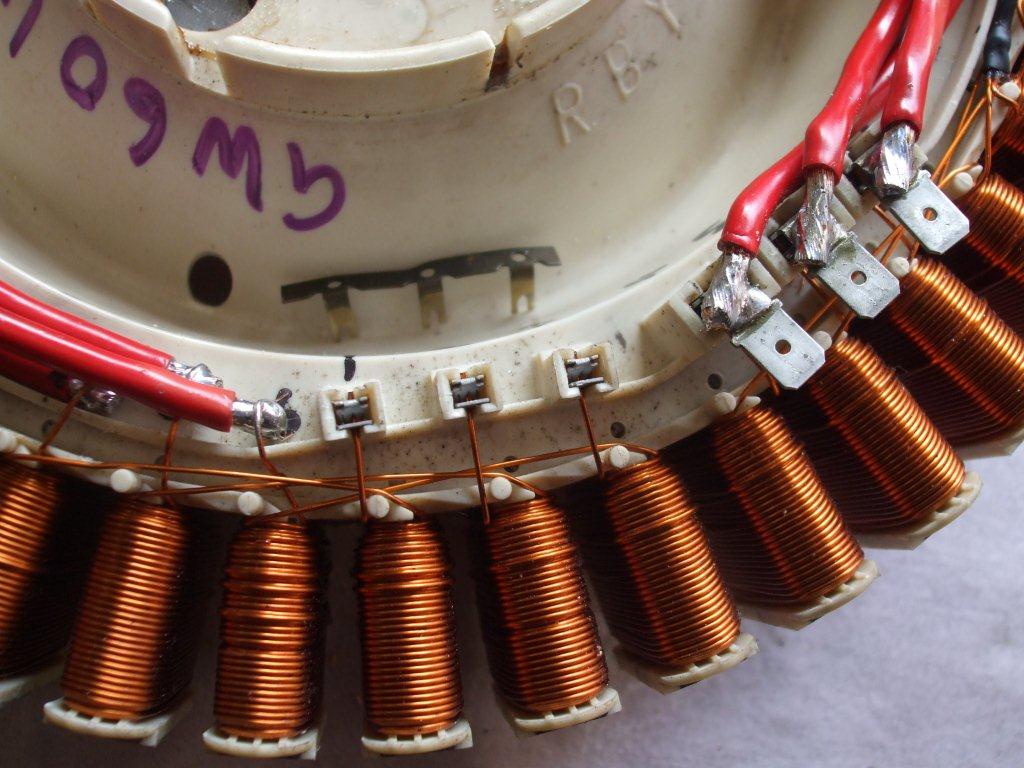

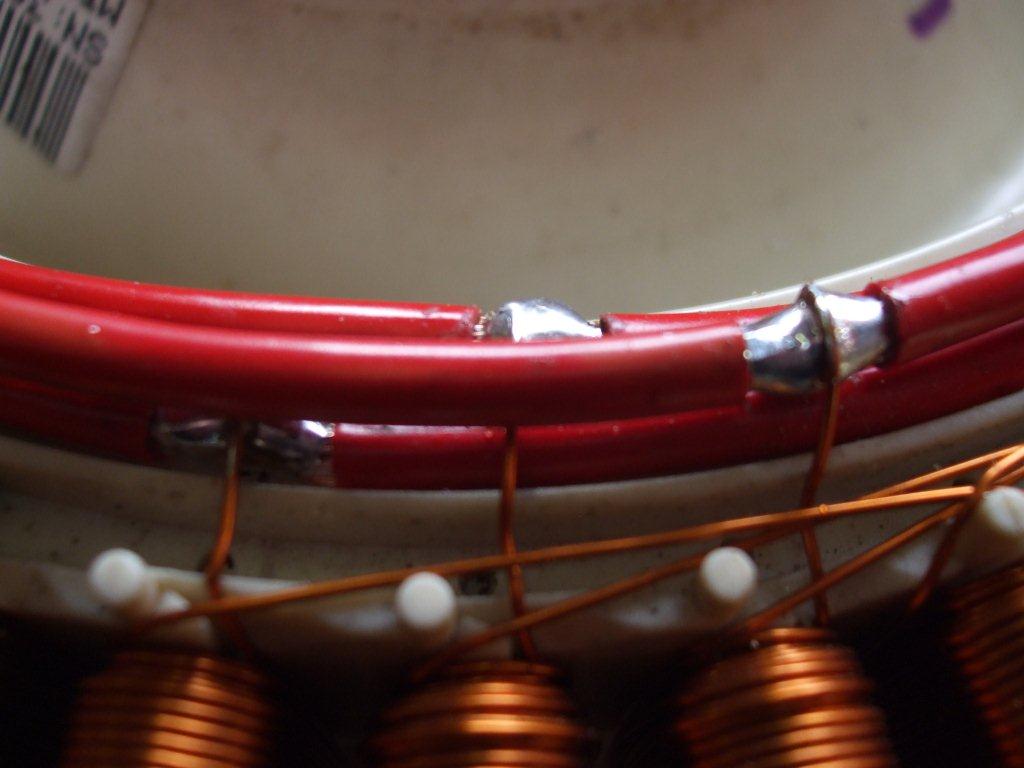

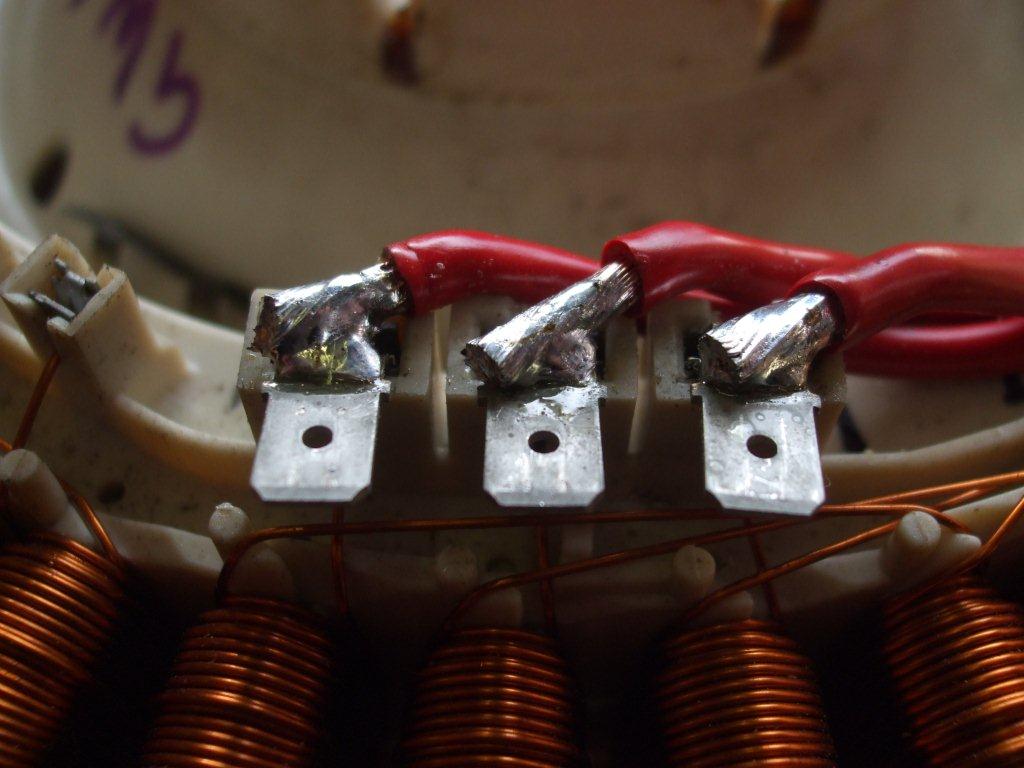

I found a link last night to a site where a guy is doing the same configuration although I think he explains it far better than I could, here it is: http://www.watchtv.net/~rburmeister/smart%20wiring.html Wow, lots of soldering later & I’m done, I would recommend using the link on how to do this, the guy explains it very well with great pics of his progress. I have also added many pics of my own progress as well. I used 3 lengths of 475mm long wire, a little bit of heat shrink to cover the connection of the 3 coil wires each time, plus I soldered the 475mm wire to the back of the crimp terminals so I could still use the front of the terminals to slide crimps on to, I also didn’t need to use any cable ties or secure the wire in any way, the wire was firmly in place after being soldered to all the points, maybe the wire I used was less flexible, apart from that I done it much the same as the link earlier. I also masked off the area of the terminals that the crimps would attach to before I spray varnished the whole thing. So I’m almost done, I’ve been putting some thought into how I’m going to balance the blades, if I don’t do it then the whole thing could rattle itself to bits, a bit like those ceiling fans that hang down & wobble & really annoy me in shops & restaurants. Every time I see a wobbly ceiling fan it drives me crazy, maybe I spend too much time on my own in the workshop but it really doesn’t take much to rectify the problem. I’ve installed some of those ceiling fans before & what I used to do was hold a tape measure between the ceiling & the tip of the fan blade & make sure each blade was at the same height by adding a few washers to each blade to bring it down in line with the others. This idea worked well & I’m going to try & do the same here, exactly how I’m not sure but it can’t be too hard can it. Ok, I had a think about this balancing thing & ended up taking the motor off the shaft & putting the set of blades on to the shaft, it fits very loosely on the end, I put a nut on the end of the shaft but only to stop the blades coming off. With one blade pointing straight down I was able to easily balance the 2 at the top by adding a washer or 2, then do the same with the next blade pointing straight down & so on. It worked really well & I was able to balance it perfectly within half an hour. It surprised me that they needed balancing as much as they did because I spent a lot of time getting each blade to be exactly the same as each other. I suppose even the mass produced ceiling fans still need balancing so I shouldn’t be surprised that my home made storm water pipe blades needed it as well. |

If you like our site then please click on the Facebook icon at the top right of this page, thank you.

For more information you can email us via our Contact Us page.