I don't want to go into too much detail here as the design will depend on the materials that are used, my design is definitely based around some old commercial greenhouse frames and 2 commercial stainless steel kitchen work tops.

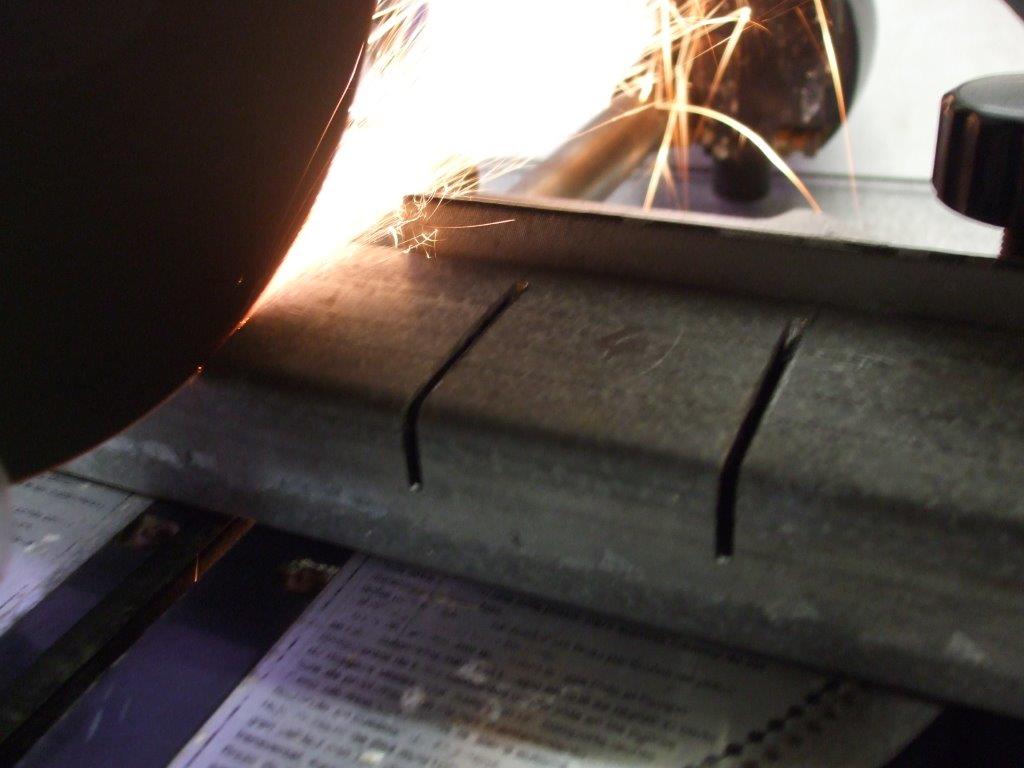

I've tapped & screwed the entire frame together, it would have been much easier to weld it but I like the idea that I can dismantle it & easily take it up to the roof in pieces. I used some stainless steel brackets to help join some of the frame together. All the fixings are stainless steel, with the majority being M5 tapped & screwed especially when using the brackets as shown below. The 3 angled uprights are secured to the horizontal lower rail by one M8 bolt in each.

The whole frame is very light, I can lift it on my own, it's just an awkward shape to move on your own.

When the second stainless steel sheet is fixed in place there will be a gap between the sheets similar to the gap between the lower sheet & the bottom rail. There will also be a gap between the top sheet & the top manifold box. This is so the wind can dissipate through the frame, I suspect without the gaps that it would act as a big sail & put far too much stress on the roof. This is obviously not a problem if you are mounting it flat on a pitched roof. The stainless steel sheets should reflect the sun that comes between the tubes back onto the back of the tubes which should improve the heat output considerably.

The whole frame is very light, I can lift it on my own, it's just an awkward shape to move on your own.

When the second stainless steel sheet is fixed in place there will be a gap between the sheets similar to the gap between the lower sheet & the bottom rail. There will also be a gap between the top sheet & the top manifold box. This is so the wind can dissipate through the frame, I suspect without the gaps that it would act as a big sail & put far too much stress on the roof. This is obviously not a problem if you are mounting it flat on a pitched roof. The stainless steel sheets should reflect the sun that comes between the tubes back onto the back of the tubes which should improve the heat output considerably.

The hardest thing with making this frame was getting the correct material at a good price, again don't rush into buying new stuff, next time you drive pass a scrap dealer just pop in & see what he has. If you are willing to part with the money to buy all the materials new then I would suggest it would be cheaper to buy a complete frame along with the tubes & heat pipes from an online auction. But where's the fun in that.

If you like our site then please click on the Facebook icon at the top right of this page, thank you.

For more information you can email us via our Contact Us page.